sample analyzing

- sample analyzing

- cleaning and washing

- rasping and milling

- cyclone de-sanding

- centrifugal extracting

- refining

- solid - liquid separation

- drying and screen

- weighing and packaging

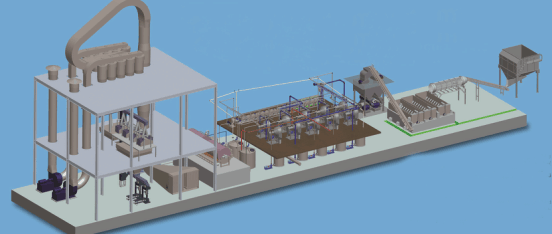

FLOW CHART:

PRETREATMENT:

Mix fresh potato residue with acid in the blender, then convey the potatoes to the secondary centrifugal sieve with the function of sterilization, then to dehydration centrifugal sieve for preliminary dehydration.

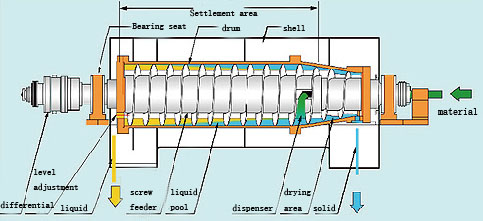

CENTRIFUGAL DEHYDRATION:

After the initial dehydration, the potatoes enter into the closed horizontal spiral centrifuge for dehydration which will further reduce the water content.

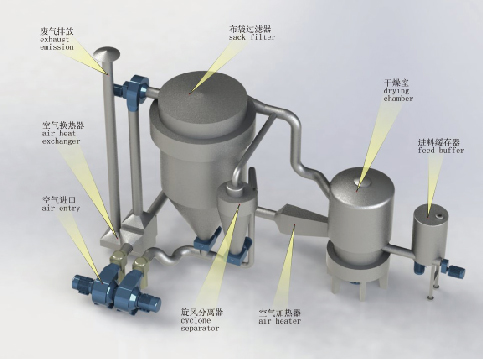

DRYING:

The dehydrated fiber enters into rotary flash drying machine system for drying process.

SCREENING:

The dried fiber will be further screened so as to maintain the similar size.

PACKAGING:

Pack according to clients’ requirement after screening.

ADVANTAGES:

High fiber extraction rate (95%)

Good quality (food grade, water holding capacity can reach to 20)

Low consumption (the consumption of drying is only 50% of the regular one)

High automatic degree (can be unmanned operated)

Application area:

Meat and sausage

Reduce the consumption of fat and weight in the process of heating (such as smoke), improve the structure of the organization, and retain the water and oil.

Bread and baked food

Strengthen dietary fiber, reduce calories, prolong the shelf life, and stabilize gluten structure.

Health food

Strengthen dietary fiber, reduce calories and help digest.

Puffed food and pasta

Strengthen dietary fiber, improve the structure of the organization, and enhance water resistance and crispness

Main equipment:

Rotary flash drying system

The principle diagram of the horizontal fiber screw centrifugal machine