Application:

De-sanding cyclone functions as key equipment in starch process for removing sands and other heavy particles from rasp slurry after rasper. It works before starch extraction process, which can protect the equipment thereafter, prolong the whole production line operation life, and improve starch quality. De-sanding cyclone can be used to remove heavy particles from other fluids as well.

Features:

1. Unique ceramic cyclone tube for high efficiency and durability.

2. full-automatic sand discharging system by pneumatic control and special ballonet valve, accurately controlled.

3. Wholly in stainless steel (can be partly in carbon steel upon customer’s request.)

Structure and principle:

After being pumped into de-sanding cyclone tube, slurry milk swirls inside the tube with high speed. By the force of centrifugal effect, lighter substance (starch) swirls out through overflow pipe, and heavier matters (soil, sands, etc) settle down along the conical cyclone tube and are discharged from the bottom valve.

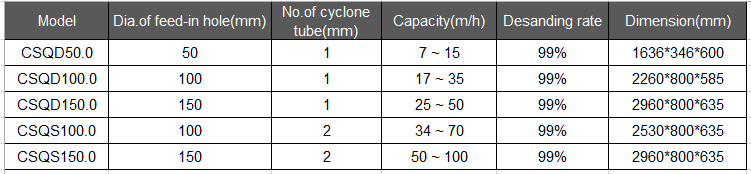

Parameters: